Designação do projeto: INOVA - MAX 4.0

Localização: Pombal

Prazo execução: 24 meses (01/07/2019 a 30/06/2021)

Investimento elegível: 12.996.300,00 Euros

Incentivo não reembolsável: 3.249.075,00 Euros

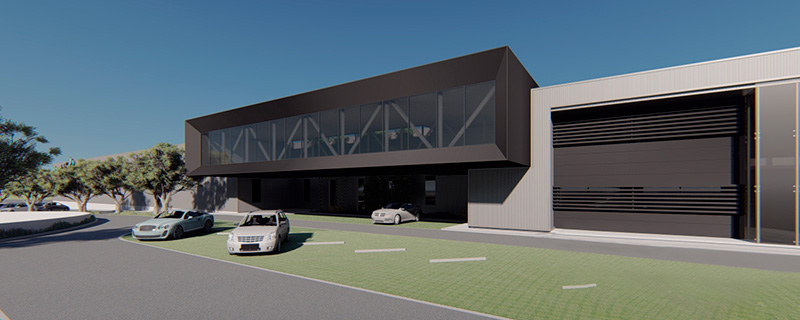

O projeto está inserido no plano de expansão da atividade, com a ampliação das instalações para o dobro das atuais, incluindo a construção de 2 novas naves industriais, para a instalação de novas células de injeção de maior tonelagem (até 2.300 toneladas).

O investimento inclui ainda a construção de um novo armazém capacitado com a mais moderna tecnologia de logística interna, recorrendo a veículos de condução autónoma (AGV automated guided vehicle).

O presente projeto de investimento passará também pela oferta de novas tecnologias para a produção de peças plásticas como IMD, Variotherm e Muccel, de forma a responder às atuais e futuras necessidades dos clientes.

Hoje, a MAXIPLÁS ainda utiliza os métodos normais de produção, com grande incorporação de recursos humanos nas várias tarefas de produção e montagem de peças. As máquinas dispõem de simples robots apenas para retirar as peças da máquina e colocar no tapete ao lado da máquina, sendo o operador que depois irá dar seguimento ao processo de forma manual.

Após a implementação deste projeto, vão ser adquiridos 4 robots de 6 eixos de forma a conseguirmos criar células de produção automatizadas, em que os robots tiram as peças da máquina, fazem todas as operações acessórias (por exemplo etiquetagem, montagem, soldadura de peça, colocação de insertos...) e embalam a peça, concluindo todo o processo sem intervenção de recursos humanos. Depois a embalagem segue para armazém, de forma também automatizada uma vez que se vai colocar um AGV (porta paletes automatizado) a circular sozinho pela fábrica.

Designação do projeto: Novas Instalações da MAXIPLÁS

Código do projeto: POCI-02-0853-FEDER-018870

Objetivo principal: Reforçar a competitividade das pequenas e médias empresas

Região de intervenção: Pombal

Entidade beneficiária: MAXIPLÁS – PLÁSTICOS DE ENGENHARIA, LDA.

Data de aprovação: 16-11-2016

Data de início: 01-04-2016

Data de conclusão: 31-03-2018

Custo total elegível: 5.555.546,00 euros

Apoio financeiro da União Europeia: FEDER – 2.777.773,00 euros

– Melhorar a eficiência do processo produtivo, designadamente ao nível da automatização e evolução nas máquinas produtivas mais precisas e tecnologicamente avançadas;

–Aumentar o nível de faturação mantendo uma margem bruta favorável e controlando os gastos correntes, demonstrando a viabilidade do projeto na empresa;

– Entrar em novos setores de atuação para além do setor automóvel, para existir uma maior diversificação das peças injetadas e aumentar as exportações diretas;

– Intensificar as relações com os fornecedores de 1ª linha – Tier1;

– Diferenciar-se cada vez mais da concorrência direta e indireta em termos de qualidade técnica e cumprimento de prazos;

– Evoluir ao nível do pessoal, criando mais postos de trabalho qualificados e oferecendo formação aos atuais, nas áreas de maior necessidade;

– Reduzir o peso dos subcontratos na estrutura de gastos da empresa.

Resultados a atingir:

– Realizar um investimento tanto em nova maquinaria como em obras de construção/remodelação a rondar os 6.200.000,00 euros até março 2018;

– Alcançar um volume de faturação superior a 8.500.000,00 euros em 2020;

– Reduzir até 2020 em pelo menos 5% o peso da indústria automóvel no total de peças plásticas injetadas;

– Atingir uma taxa de exportação direta de pelo menos 20% em 2018;

– Iniciar uma nova parceria com pelo menos mais um fornecedor Tier1;

– Criar pelo menos mais 10 postos de trabalho até final de 2018, aumentando em mais de 10% a taxa de licenciados;

– Diminuir a subcontratação em cerca de 2% face ao total da faturação até 2020.